What is EnviroRinse™

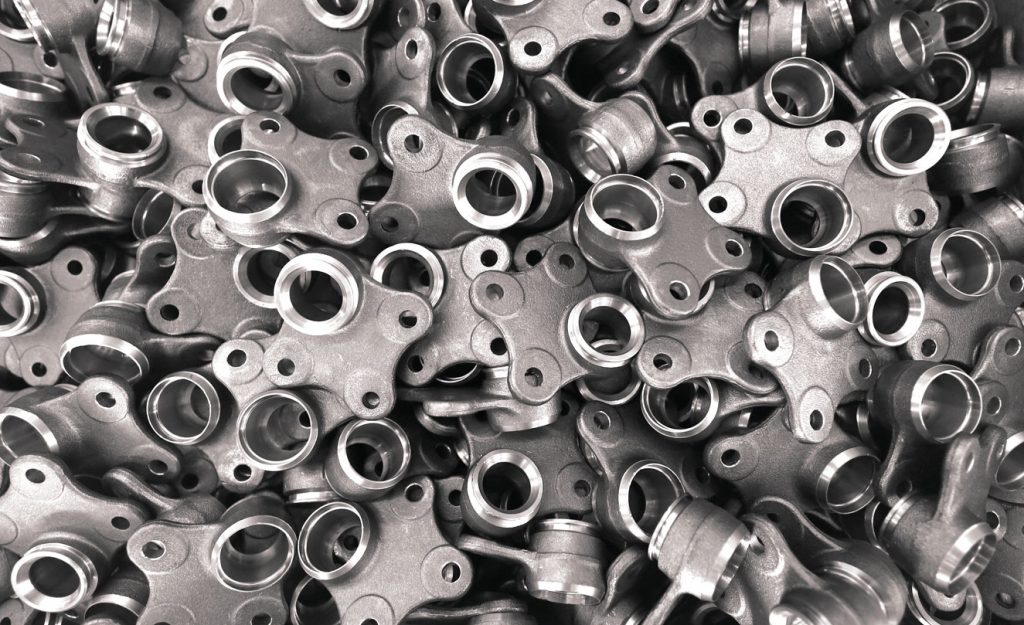

An environmentally responsible rinse solution, EnviroRinse™ is the first rust preventative designed to be added directly into dip tanks and aqueous parts cleaning machines to provide effective, long-term corrosion protection for machined components

A water-based, bio-based, and biodegradable rust preventative that gives up to two years corrosion protection of most metals in storage and during transportation

Unlike traditional rust preventative oils, EnviroRinse™ protects against corrosion without leaving any residues. This means that there is no tough cleaning to remove oils, no quality risks, and no loss of time. EnviroRinse™ leaves a dry uniform film on the surface of the metal that is virtually undetectable and easily removed using a weak acid or alkaline solution. Workspaces are now more clean and manufactured components are both cleaner and easier (non-slip) to handle.

Why is it needed?

Corrosion of machined components is a costly problem, particularly during the transportation and long-term storage. Effective corrosion management is necessary for successful operations, without it companies could face the following threats:

- Costly and labour-intensive re-work/de-rusting

- Scrappage of components

- Quality control rejections

- Customer rejections

- Reputation damage

By using EnviroRinse™ as part of your corrosion protection regime, you will significantly reduce non-conformities, rework time and costs and customer complaints.

Product Comparison

EnviroRinse™

EnviroRinse™ is the first rust preventative solution that can be added directly into a dip tank or aqueous washing machine to give you long-term corrosion protection, saving you…

- Costs

- Manpower

- Time

- Non-conformities

Ultimately leading to happier customers.

EnviroRinse™ stands out due to its effectiveness against corrosion. This is why EnviroRinse™ is already approved by many OEMs and automotive suppliers.

Long-term, multi-metal protection

Provides excellent multi-metal corrosion protection for up to 24 months when stored indoors.

EnviroRinse™ provides excellent long-term corrosion protection (up to two years) for most metals* including iron, steel, cast iron, tin, zinc, aluminium and combination metals.

*Not intended for use with yellow metals (copper, brass, etc.)

Cost reductions

Corrosion of any manufacturing or engineering components can have costly repercussions due to the requirement for these parts to be reworked.

Investment in EnviroRinse™ provides a simple but effective way to reducing costs in several areas:

- Time is money – EnviroRinse™ reduces the number of cleaning and protecting processes during the manufacturing process

- Replaces hazardous mineral oils and flammable solvents, eliminating their expensive disposal costs

- Provides long-term protection during storage leading to reduced wastage

- Additional corrosion packing such as VPI Paper is no longer required

- Long-term corrosion protection during transportation leads to less non-conformities and reworking and happier customers

Automated processes

Directly added into the rinse tank in aqueous cleaning machines eliminating extra processes and manpower leading to an automated process

Residue free and no aggressive clean cycles

Workspaces are now more clean and manufactured components are both cleaner and easier (non-slip) to handle.

Unlike rust preventive oils, EnviroRinse™ protects against corrosion without leaving any residues. This means that there is no tough cleaning to remove oils, no quality risks, and no loss of time.EnviroRinse™ leaves a dry uniform film on the surface of the metal that is virtually undetectable and easily removed using a weak acid or alkaline solution.

Corporate social responsibility

Formulated with renewable raw materials, EnviroRinse™ is an environmentally friendly and biodegradable alternative to petroleum derived products.

The components of EnviroRinse™ have a gentle effect on the environment and contains no chlorinated compounds, chromates or nitrites.

Less non-conformities

Every management system requires a way for approaching non-conformities and potential non-conformities.

By integrating EnviroRinse™ as part of your corrosion protection regime you will reduce non-conformities, customer complaints and poor or adverse results.

The less time it takes to rework components, the more time can be spent operating efficiently and safely.

Reduced packaging

Can reduce VCI film in most applications, significantly reducing packaging and associated recycling costs.

Value Added Services

The expertise of our engineers and chemists permits us to offer our clients timely technical support to develop tailor-made solutions for special applications

- Lake Engineering Solutions will survey your site pinpointing corrosion locations during component manufacture, storage, and transportation

- We will recommend the right products to help you reduce the risk of corrosion and document corrosion control procedures

- Provide standard operating procedure and full monitoring documentation

- Lake Engineers will initially aid or supervise applying the solution as well as provide comprehensive training to the end users