Lake Engineering Solutions supply a wide range of Cortec VpCI® Emitters to suit a number of applications.

Vapour phase Corrosion Inhibitors (VpCI®) Emitters are installed in small, enclosed areas with little or no ventilation such as electronic cabinets, controller panels and junction boxes. The VpCI® emits vapours, which form a thin molecular layer on internal metal surfaces to protect critical, complex, and expensive electronic equipment during operation, shipping, or storage.

EcoEmitter®

EcoEmitter® is a highly engineered device designed to provide corrosion protection for your most sensitive assets such as electronic and optical equipment and components. Each individual emitter will protect volumes up to 0.25 m3. Nano-VpCI™ emit from the device and saturate the enclosure via diffusion, filling all void spaces and recessed areas with protective vapour molecules. These molecules are attracted to and adsorb onto metallic surfaces resulting in the formation of nanofilms, very thin microscopic molecular layers of corrosion protection. The nanofilms formed do not adversely affect or alter the appearance, conductivity, or optical functionality of the components protected.

EcoEmitter® was designed with the environment in mind in a concerted effort to reduce our carbon footprint. The polymeric cup has been redesigned to replace polyethylene and is constructed from OK Biobased 3-Star rated resins containing 60-80% renewable carbon content. The active corrosion inhibiting powder is nontoxic and biodegradable. The traditional Tyvek® membrane used on VpCI®-105 and VpCI®-111 Emitters has been replaced with a breathable membrane constructed from 100% biobased fibers.

VpCI® 101

VpCI®-101 devices are designed to provide corrosion protection for metal components and parts enclosed in non-ventilated control boxes, cabinets, or tool boxes. A VpCI®-101 device protects up to 28 litres in volume. VpCI®-101 is a small patented device from which Vapour phase Corrosion Inhibitors are slowly released. The corrosion inhibitors emit vapours that form a molecular layer on metal surfaces to protect critical, complex, and expensive electronic equipment and other metal components during operations, shipping, or storage. VpCI®-101 provides long-term protection against corrosion even in the presence of adverse conditions including salt, moisture, airborne contaminants, H2S, SO2, NH3, and others.

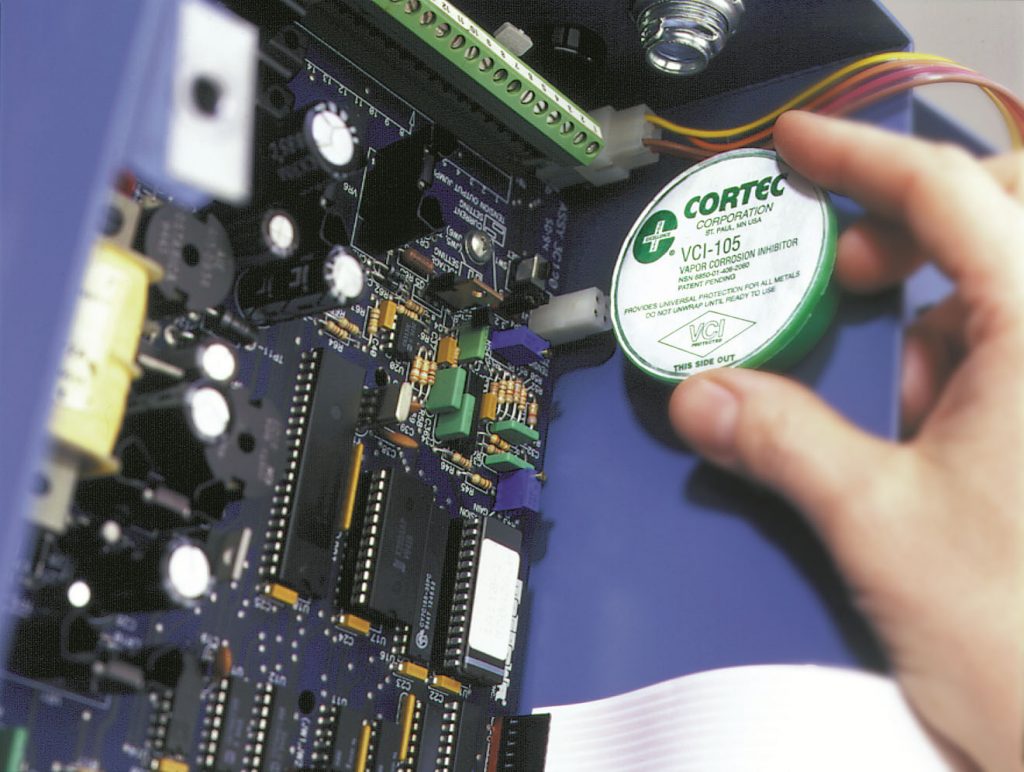

VpCI® 105

VpCI®-105 emitters are unique devices designed to provide corrosion protection for metal components and parts enclosed in non-ventilated control boxes, cabinets, or tool boxes up to 141.6 litres. The VpCI®-105 device emits Vapour phase Corrosion Inhibitors, which form a protective coating on all metal surfaces. VpCI®-105 is a patented plastic emitter with a breathable Tyvek® membrane through which the corrosion inhibitor is released.

It provides long-term protection against corrosion even in the presence of adverse conditions including salt, moisture, airborne contaminants, H2S, SO2, NH3, and others.

VpCI® 111

VpCI®-111 emitters are unique devices designed to provide corrosion protection for metal components and parts enclosed in non-ventilated control boxes, cabinets or tool boxes up to 312 litres. The VpCI® emits vapours, which form a molecular layer on internal metal surfaces to protect critical, complex, and expensive electronic equipment during operation, shipping, or storage. VpCI®-111 is patented with a breathable Tyvek® membrane cover through which corrosion inhibitors are slowly released. VpCI®-111 provides long term protection against corrosion even in the presence of adverse conditions including salt, moisture, airborne contaminants, H2S, SO2, NH3, and others.

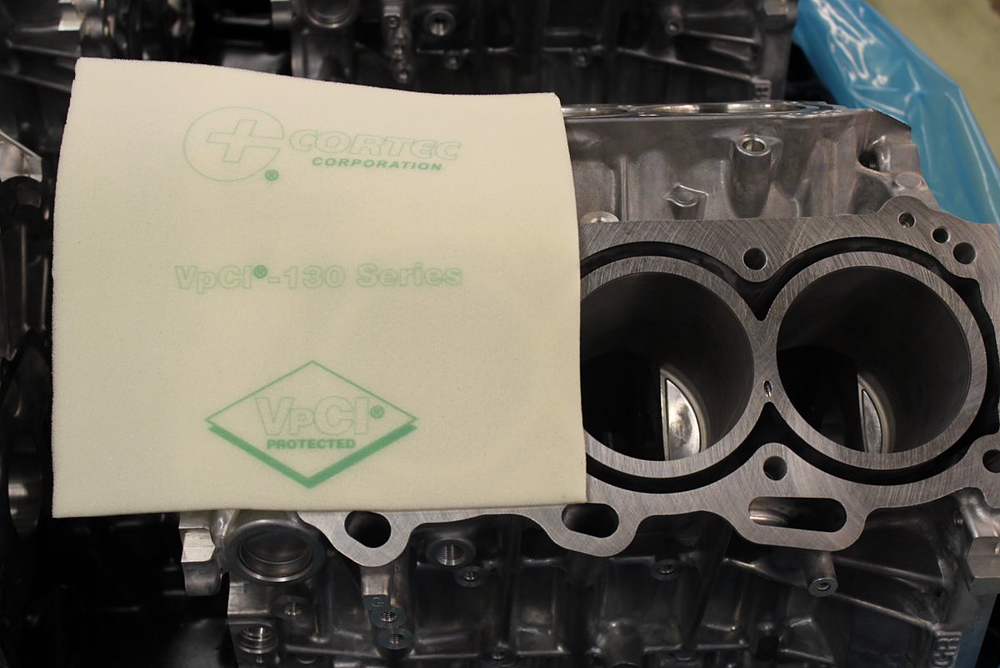

VpCI®-130 Series

VpCI®-130 Series Foams are unique flexible packaging materials that combine VpCI® protection, and desiccant action; plus excellent antistatic capabilities all in one step! You can now eliminate expensive and messy rust preventatives with VpCI®-130 Series Foams. Parts protected are always ready for use; no degreasing or coating removal is required. Application of multifunctional materials such as VpCI®-130 Series Foams results in significant weight and labor savings.

Metal parts packaged with VpCI®-130 Series Foams receive continuous protection against humidity, condensation, aggressive industrial atmospheres, dissimilar metal corrosion (galvanic corrosion), salt air, and residual impurities left after processing.

Corrosorber®

Corrosorber® absorbs hydrogen sulfide, volatile mercaptans, and other corrosive gases, removing them from the atmosphere and eliminating the cause of some damage to metals. The chemicals contained in Corrosorber® have been treated to change color from off-white to black as corrosive gases are trapped. Corrosorber® will not interfere with VpCI® protection. Unlike other products on the market, Corrosorber® will not release the corrosive gases back into the atmosphere. The reaction is irreversible, eliminating any concern about post-contamination.

Application: Install the Corrosorber® at the earliest possible time, before shipping or receiving if possible. Simply select a space where corrosion protection would be useful, and attach using self adhesive backing. Replace cup as soon as the container appears grey. In-use temperature: 0-60 °C.

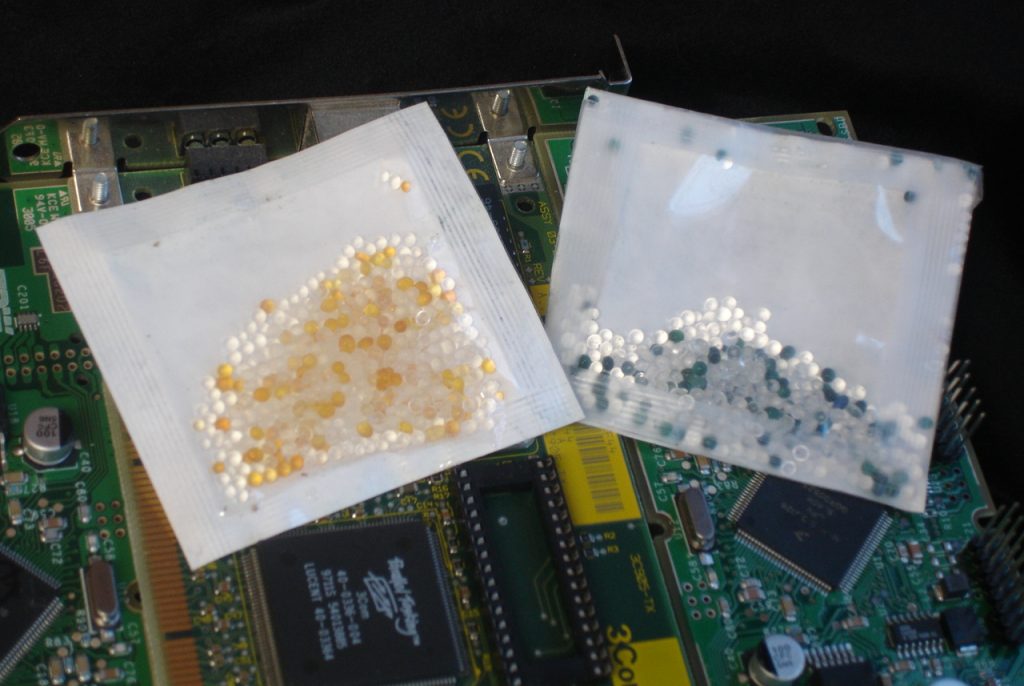

Desicorr®

Desicorr® VpCI® is a specially designed , two – sided pouch containing a unique combination of desiccant and Vapour phase Corrosion Inhibitor (VpCI®) Technology. Desicorr® VpCI® Pouches are ideal for protecting packaged ferrous and non-ferrous metals from corrosion for up to two years.

Unlike conventional desiccants, the dual function of the Desicorr® VpCI® Pouches reduces moisture in the air (desiccant action) and provides multi-metal protection (VpCI® action) within a package. In essence, the desiccant action allows the VpCI® to have free access to the surface of the metal, without competition from moisture on the metal surface.

Desicorr® VpCI® Pouches are available in both windowed and non-windowed versions (NW). The windowed version contains some indicator spheres that will change color from yellow to green when the desiccant is fully spent.

Latest news, industry insights and events

Discover the latest product news, industry insight articles from Lake Engineering Solutions.