Corrosion protection of semi-finished or machined metal components during transit and storage is critical to product quality and customer satisfaction. The choice of corrosion inhibiting technology can address costs arising from component rejects or reworks, and reduce your time spent dealing with customer complaints.

EnviroRinse™ is a corrosion inhibiting rinse solution applied immediately to washed-clean metal components and offers corrosion protection in a range of engineering industries manufacturing precision components.

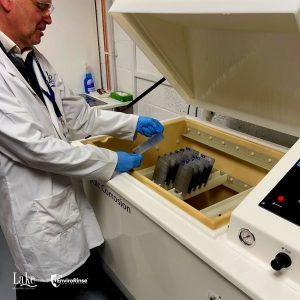

An important aspect in the implementation of EnviroRinse™ solution is the testing capability of Lake Innovation Services laboratory in Redditch, UK. Metal components taken direct from our client’s process can be tested to ‘ASTM D1748 – Standard Test Method for Rust Protection by Metal Preservatives in the Humidity Cabinet’. ASTM D1748 is the industry recognised accelerated test method for environmental conditions of temperature and humidity and is most appropriate for metal components in sheltered storage and transit.

(Corrosion Chamber with Test Panels following the most suited ASTM specification)

Alternative accelerated tests for corrosion include salt spray testing such as ISO 9227 and ASTM B-117. These test methods are an appropriate measure of long-term service of paints in a range of environmental conditions, up to and including, marine and offshore protection of structural steel. For temporary corrosion protection during storage and transit, caution is advised when making predictions based on the aggressive environment of salt spray.

Want to know which solution is best for your needs? Speak to Lake Corrosion Engineer Dean Kenny for advice on the appropriate testing of component parts.

Written By Hugh Roarty – Lake Coatings, Innovations Manager