Protecting Precision Machined Components

Lake Engineering Solutions work innovatively to analyse corrosion problems and develop workable solutions to automate workflows, provide long-term protection, prevent non-conformities, and reduce costs.

Our EnviroRinse™ solution serves across a range of fast-moving engineering industries who manufacture precision components, allowing them to continue to innovate whilst knowing component corrosion and failure is no longer an issue.

Industries served include:

- Automotive

- Commercial vehicles

- Construction Equipment

- Oil and Gas

- Power Generation

- Medical

- Aerospace

- Food & Drink Processing

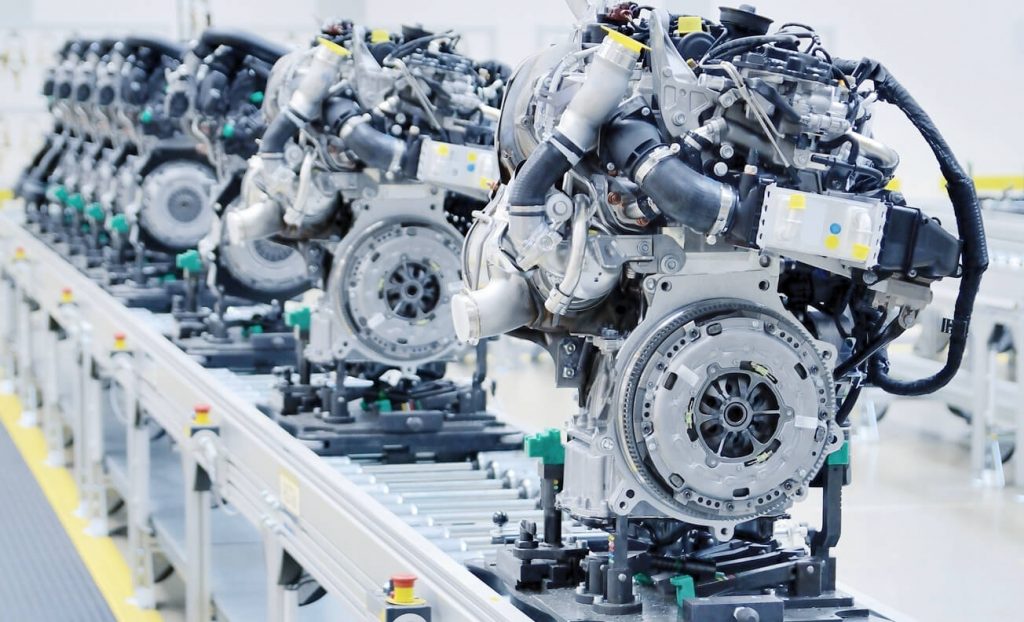

Automotive & Commercial Vehicles

The automotive and commercial vehicle sector is the largest market globally for precision machined or cast components. These components are manufactured to tight tolerances and quality assurance is critical. The application of EnviroRinseTM gives confidence to OEM’s and their supply chains that these components will reach their destination corrosion free and will remain so during long term storage.

Aerospace

The Aerospace industry, both civil and military, is vital to the security and accessibility of the entire world. In this industry, corrosion protection of critical components with tight tolerances is often requested by the end user. The incorporation of EnviroRinseTM into the manufacturing process ensures components will remain corrosion free.

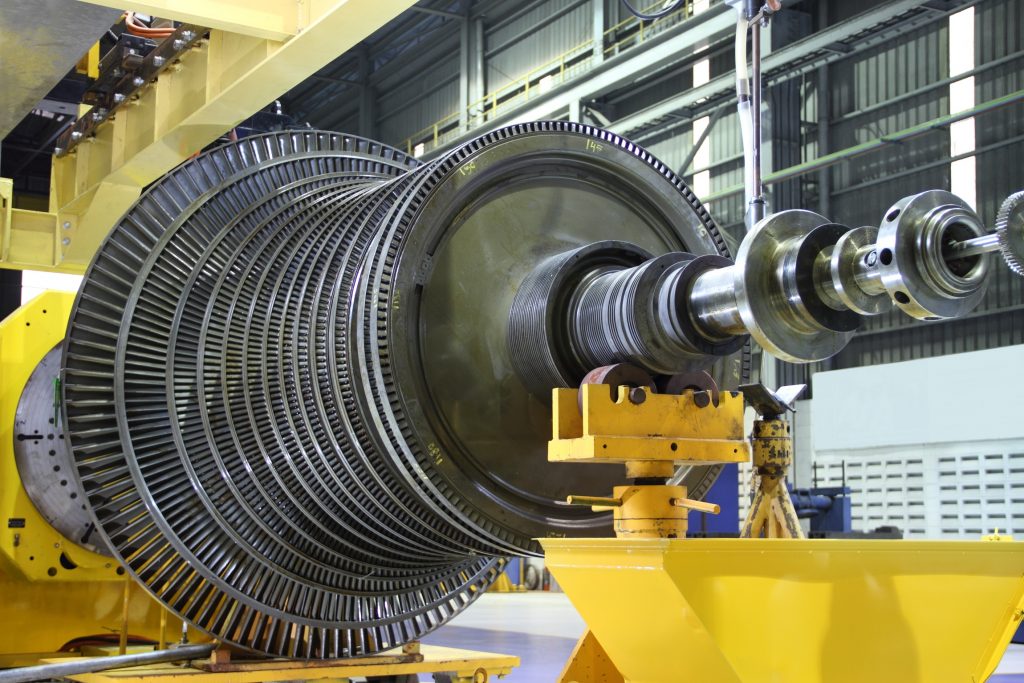

Power Generation

The strict quality and safety standards of the Oil and Gas and Power Generation industries require precision components with extremely tight design tolerances and full traceability due to the extreme environments in which these components are used. The on-site arrival of these components corrosion free is critical and can be achieved by incorporating EnviroRinse™ in the manufacturing process.

Latest news, industry insights and events

Discover the latest product news, industry insight articles from Lake Engineering Solutions.