Sustainable Solutions

Lake Engineering Solutions offer a wide range of Biobased and water-based products as environmentally friendly alternatives to mineral oil or solvent based products. These can be used in many areas including cleaning and surface preparation, bio-fuels, water treatment, metalworking, rust prevention, and lubrication.

EcoClean® Biodegradable Scale and Rust Remover Powered by Nano-VpCI®

EcoClean® Scale Remover is a heavy duty biodegradable scale and rust remover. It is one of the fastest acting products on the market for dissolving heavy scale, corrosion, and naturally occurring oxides off metals. It is effective and safe to use on iron, carbon steel, stainless steel, copper, aluminum, magnesium, and their alloys. Powerful corrosion inhibitors contained in the scale remover protect treated metals from flash rust.

EcoClean® Scale Remover is simple to use and non-toxic, providing one safe remover for all your descaling and de-rusting needs.

VpCI®-422 Rust Remover

VpCI®-422 is a rust remover that is harmless to people while effectively removing rust and tarnish from steel, iron, copper, brass, chrome and aluminum. VpCI®-422 removes corrosion from metal without creating waste disposal difficulties. Use VpCI®-414 or VpCI®-419 for added protection

It will not harm human skin or adversely affect most paints, plastics, wood, textiles, ceramics or rubber when used as recommended. Removing corrosion from metal is easy. Just apply VpCI®-422 and rinse with water.

VpCI®-423 Gel Rust Remover

VpCI®-423 is a rust remover that is harmless to people while effectively removing rust and tarnish from steel, iron, copper, brass, chrome, and aluminum. VpCI®-423 removes corrosion from metal without creating waste disposal difficulties.

When used as recommended, VpCI®-423 will not harm human skin or adversely affect most paints, plastics, wood, textiles, ceramics, or rubber. Removing corrosion from metal is easy. Apply VpCI®-423 and rinse with water then use VpCI®-414 or VpCI®-419 for added protection.

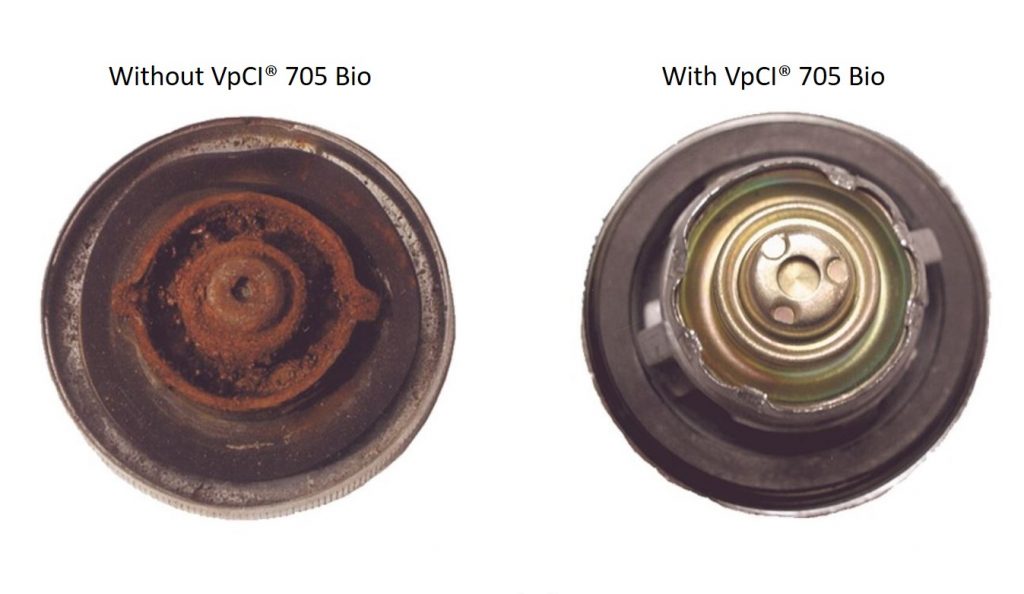

VpCI®-705 Bio

VpCI®-705 Bio is specially formulated for use as a multifunctional fuel additive to biodiesel and other bio-fuels. It serves as a corrosion inhibitor, fuel stabiliser, and water emulsifier for biodiesel, diesel, and gasoline. VpCI®-705 Bio provides corrosion protection, lubricity and elastomer protection for biobased fuels. As a fuel stabiliser, this product provides better engine performance.

VpCI®-705 Bio provides excellent corrosion protection for all of the common engineering metals used in automotive fuel systems including aluminum, aluminum die cast and zinc die cast alloys, tinplate, copper, ferrous alloys, cast iron and solder. VpCI®705 Bio gives unique multimetal corrosion protection in all phases: liquid, interface and vapour phases above and below the fuel level.

Biopad®

BioPad® is a unique flexible corrosion inhibiting device constructed from biobased non-woven material. BioPad® provides an eco-friendly sustainable packaging option for corrosion inhibition. Its high VpCI® concentration, in combination with thin design, results in material reduction by up to 94% in comparison to similar polyurethane foam emitting devices.

BioPad® is easy to use. Simply placing the correct size BioPad® into your package will allow metal items to be protected. Parts protected with BioPad® are always ready for use; no degreasing or coating removal is required; just remove the item from the package and put to use.

CorShield VpCI®-146

CorShield® VpCI®-146 is the premium corrosion inhibiting paper in the industry. It relies on Cortec’s patented Vapour phase Corrosion Inhibiting Technology, which has revolutionised the way metals are protected in an enclosed package.

Both sides of CorShield® VpCI®-146 paper offer effective protection to ferrous and nonferrous metals, eliminating the need to stock a variety of papers for different metal types. All that is needed is to wrap items in the paper and fold the edges together, using adhesive tape as needed to hold paper in place.

The VpCI® coating on the paper vapourises, reaching all metal surfaces within the package to provide complete corrosion protection with a very thin, very effective VpCI® layer that does not alter product appearance or require removal before further finishing or use.

CorShield® VpCI®-146 paper is made from 100% recycled content paper and is fully recyclable/repulpable.

EcoShield VpCI®-144

EcoShield® VpCI®-144 is the premium recyclable and repulpable moisture barrier corrosion inhibiting paper in the industry. It is coated with a water-based barrier coating and shows excellent oil and grease resistance.

Historically, polyethylene and wax coatings have been used to seal porous paper to provide a moisture barrier and/or moisture-vapour barrier. When coated this way, the resulting paper product is an environmental problem and cannot be recycled through normal channels. EcoShield® VpCI®-144 paper provides a competitive environmentally friendly alternative to polyethylene and wax paper, with comparable water vapour barrier properties. It is fully recyclable/repulpable into other types of paper products such as boxes, cardboard, and other corrugated materials.

Eco-Corr Film®

Eco-Corr Film® is the first biodegradable corrosion inhibiting film that contains Cortec’s proprietary VpCI® Technology and provides

excellent contact, barrier, and vapour-phase corrosion protection for ferrous and non-ferrous metals.

Eco-Corr Film® will disintegrate into carbon dioxide and water within 2-3 months in a commercial composting environment. The exact time for films to biodegrade is dependent upon the conditions and activity of the disposal environment (temperature, soil quality, activity of microorganisms). Eco-Corr Film® is shelf stable and will not break down prematurely until disposed of in a proper composting environment. It is compostable and compliant to ASTM D6400 (BPI #051109-C).

EcoWorks® Biodegradable & Compostable Films & Bags

Eco Works® ESD is a range of formulations, not a single product and can be customised to your precise needs. Designed with the environment in mind, Eco Works® ESD contains renewable raw materials ranging from 5 – 45%, depending upon the formulation as well as anti-static properties, which reduce or eliminate static buildup. Designed to replace traditional low density and high density films, Eco Works® ESD is suitable for industrial uses. All Eco Works® ESD formulations are certified compostable per ASTM D6400 and EN 13432 and by Biodegradable Products Institute with BPI/USCC logo.

Eco Works® ESD film and bags are recommended for packaging of static sensitive components where triboelectric charge generation is concern. They are recommended for packaging integrated circuits, printed circuit boards, PCB components, telecommunications equipment, electronic and electrical panels, and enclosures.

VpCI®-609 Powder for Ferrous Metals

Description: VpCI®-609 is a water-soluble Vapour phase Corrosion Inhibitor (VpCI®) powder for wet or dry corrosion protection of ferrous metals and aluminum. VpCI®-609 is also available as VpCI®-609 S (with silica).

Application: Apply VpCI®-609 in dry form by dusting, fogging, or sprinkling. Apply VpCI®-609 in aqueous form by spray, flush, or immersion. After application simply cover and close or seal the interior cavity or void (Fogging is easily achieved by using a low pressure air hose and sandblast cup. Large conventional sandblasting systems can also be used).

Package: VpCI®-609/609 S powders are available in 23 kg and 45 kg moisture barrier bags packed in fiber-lined drums. Also available in pouches such as EcoPouch®. To ensure best product performance, store in original packaging, indoors, and out of direct sunlight at 4-38 °C. Shelf life of 2 years

VpCI®-649 Liquid: Multimetal Closed Loop Treatment

Description: VpCI®-649 is a unique concentrated liquid formulation that protects ferrous and non-ferrous metals from corrosive solutions. In addition, this product is designed to provide long-term protection in fresh water and glycol closed loop systems. VpCI®-649 combines contact and volatile corrosion inhibitors along with anti-scalants in a formulation that does not contain nitrites, phosphates or chromates. This product helps solve the problem of disposal, particularly for large quantities of water.

Application:

• Closed loop cooling systems

• Fire extinguishing systems dry layup

• Hydrostatic testing of pipelines, casings, tanks, and valves

• Packer fluid additive

• Cooling tower layup

Package:

VpCI®-649 is available in 19 and 208 litre drums, liquid totes, and bulk. To ensure best product performance, store in original packaging, indoors, and out of direct sunlight at 4-38 oC. Shelf life of 2 years.

Latest news, industry insights and events

Discover the latest product news, industry insight articles from Lake Engineering Solutions.